a. PLATES

- BQ PLATES

- HR PLATE

- CHEQERED PLATE

- MS PLATE

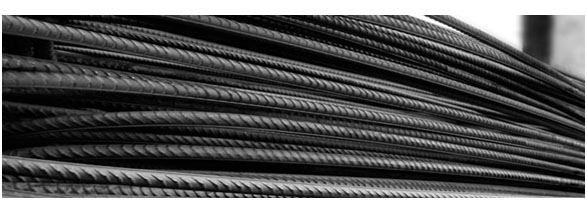

ARIHANT TMT Rebars come with a series of inherent advantages like consistent quality along with uniform grades, dimensions and tolerances. It also comes with superior stability, high strength-to-weight ratios, properties for higher durability and easy workability. The Company has received ISO - 9001, 14001 and OHSAS 18001 certifications as a testament to the fine quality of its products. SARTHAK TMT is made by most renowned GERMAN Technology with THERMAX license, sizes from 8mm-40mm providing grades Fe-415, Fe-415D, Fe-500, Fe-500D, Fe-550, Fe-550D & Fe-600.

Properties of Sponge Iron:-

Specifications:-

Manganese : 0.50% to 0.60%

Grade: Fe-415/500/550/600

Phos .: 0.05% max

Sulphur : 0.05% max

Carbon: 0.25% max

Size: 8 mm to 52 mm

|

SPECIFICATION OF TMT BARS WEIGHTS (Kg/Mtr) |

|||||||||||

| SIZE | IS-1786:2008 |

Arihant TMT |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Std |

Min |

Max |

Min |

Max |

|||||||

8mm |

0.395 |

0.367 |

0.423 |

0.370 |

0.385 |

||||||

10mm |

0.617 |

0.574 |

0.660 |

0.575 |

0.585 |

||||||

12mm |

0.888 |

0.844 |

0.932 |

0.845 |

0.860 |

||||||

16mm |

1.580 |

1.500 |

1.659 |

1.510 |

1.580 |

||||||

20mm |

2.470 |

2.395 |

2.544 |

2.400 |

2.450 |

||||||

25mm |

3.850 |

3.730 |

3.965 |

3.730 |

3.850 |

||||||

28mm |

4.830 |

4.685 |

4.975 |

4.700 |

4.830 |

||||||

32mm |

6.310 |

6.121 |

6.499 |

6.190 |

6.310 |

||||||

|

SPECIFICATION OF TMT BARS MECHANICAL PROPERTIES |

||||||||||||

|

Parameter |

IS-1786:2008 |

Sarthak TMT |

||||||||||

|

Fe-415 |

Fe-500 |

Fe-500D |

Fe-415 |

Fe-500 |

Fe-500D |

|||||||

|

Yield Stress(N/mm2) |

415 |

500 |

500 |

430-490 |

520-560 |

520-560 |

||||||

|

Ultimate Tensile Strength (N/mm2) |

485 |

545 |

565 |

500-560 |

600-680 |

600-680 |

||||||

|

Elongation(%) |

14.5 |

12 |

16 |

20-25 |

18-24 |

18-24 |

||||||

|

Total Elongation @ Max Force(%) |

- |

- |

5 |

- |

- |

8 to 10 |

||||||

|

Ration (UTS/YS) |

1.16 |

1.09 |

1.13 |

1.15-1.25 |

1.13-1.22 |

1.14-1.25 |

||||||

|

SPECIFICATION OF TMT BARS CHEMICAL COMPOSITION |

|||||||

|

Parameter |

IS-1786:2008 |

Sarthak TMT |

|||||

|

Fe-415 |

Fe-500 |

Fe-500D |

Fe-415 |

Fe-500 |

Fe-500D |

||

|

Carbon (C) |

0.30 |

0.30 |

0.25 |

0.18 - 0.25 |

0.18 - 0.23 |

0.16 - 0.22 |

|

|

Sulphur (S) |

0.06 |

0.055 |

0.04 |

0.035-0.055 |

0.025-0.050 |

0.020-0.035 |

|

|

Phosphorus (P) |

0.06 |

0.055 |

0.04 |

0.035-0.055 |

0.035-0.050 |

0.025-0.035 |

|

|

Sulphur + Phosphorus(S+P) |

0.11 |

0.105 |

0.075 |

0.070-0.110 |

0.060-0.100 |

0.045-0.070 |

|

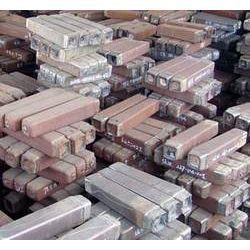

One of the most important materials needed for high quality construction is steel, which is consumed in form of bars and the best raw material to produce high quality steel bars is MS Billets. At Arihant Sales Network, we produce ideal billets that result in top quality steel bars.

Billet, being a semi-finished product, is used for feedstock to rolling mills for production of long products like wire rods, bars/rods and structural. Steel Billet is also used extensively in forge shops and machine shops for production of engineering goods and also as feedstock for seamless tubes.

Excellent Surface Finish: The Billets produced by ARIHANT are free from any surface crack or lamination. Magnetic particle test in order to identify any crack on the surface is done on a regular basis as per its Quality Management Plan. Dimensional Tolerance: Billets at ARIHANT are produced strictly in accordance to IS 2830 for dimensional tolerance.

No Internal Defects: The Billets produced are free from any internal defects. Defects such as piping blow-holes and pinholes are identified and segregated by Sulphur Print Test.

Steel is a dynamic, versatile and eco-friendly product with diverse use and applications. The liquid steel is solidified in cast iron moulds, which are placed on bottom pouring plate. The metal enters into the mould from bottom and rises up. In order to have ease in separating ingots from moulds, the moulds are tapered from top. Thus the ingots are also tapered from top. On the other hand, billets have same cross sectional area throughout its length. Billets are produced from Continuous casting Machine – CCM.

The following are the steps involved in the operation of a furnace

Specifications:- Available in all sizes & sections.

Wire rods are hot rolled products from hot charged billets

HB Wires- Wire rods are cold drawn to HB wires to sizes 6 SWG to 14 SWG.

Application Of wires Rods:-

Specifications:-

Available in Steel Grade and Foundry Grade

Silicon: below 1.5 %

Phos: 0.120 Max

Sulphur: 0.06 Max

Carbon: 3.8- 4.4 %

Mgn: 0.70

Size: 0-6 mm

|

SPECIFICATION OF TMT BARS WEIGHTS (Kg/Mtr) |

|||||||||||

| Products | Size | Chemical Composition | UTS (N/mm2) | YS (N/mm2) | % Elongation | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Wire rods |

5.5, 6, 7, 8 & 10 mm | As per MS grade | 470-510 | 330-370 | Min 33 | ||||||

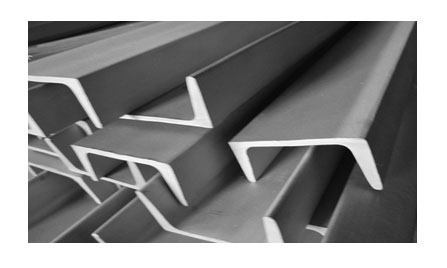

We offer the finest quality MS Angles, which are extensively used in fabrication industry. The dimension is determined by the length and the unit measurement. We trust quality and productivity.

The dimension is determined by the length and the unit measurement. We trust quality and productivity.

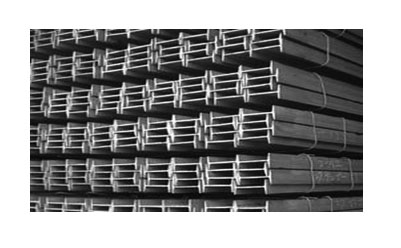

We offer the finest quality MS Beams & RS Joists which is the most sought after sections by the structural engineers, architects and construction.

The dimension is determined by the length and the unit measurement. We trust quality and productivity.

We offer the finest quality MS Channels, which are extensively used in fabrication industry. A channel is a right angle "C" section.

The dimension is determined by the length and the unit measurement. We trust quality and productivity.

Arihant sales network is engaged in offering a best quality range of Heavy Melting Scrap. These scraps are widely used in various industrial applications for making of more products. This scrap is available at affordable rates in the market.

Because of our vast experience, we have been successful in catering to the requirements of our esteemed clients by offering a qualitative range of Heavy Melting Scrap. As we never compromise with the quality of the products being offered by us, we are associated with the most reliable vendors of the market to obtain this range. Our products are made available by us in various specifications, in order th meet the variegated needs of our esteemed clients.

Features:-

Specifications:- Heavy Melting Scrap

|

SPECIFICATION OF MS ROUND BARS PROPERTIES |

|||||||||||||

|

Size in mm |

Average Weight |

||||||||||||

|

KG/MTR |

KG/FT |

||||||||||||

|

12 |

0.9 |

0.3 |

|||||||||||

|

14 |

1.2 |

0.4 |

|||||||||||

|

16 |

1.6 |

0.5 |

|||||||||||

|

18 |

2 |

0.6 |

|||||||||||

|

20 |

2.5 |

0.8 |

|||||||||||

|

22 |

3 |

0.9 |

|||||||||||

|

25 |

3.9 |

1.2 |

|||||||||||

|

Ultimate Tensile Strength (N/mm2) |

485 |

6

565 |

|||||||||||

|

Ultimate Tensile Strength (N/mm2) |

485 |

6

565 |

|||||||||||

|

Ultimate Tensile Strength (N/mm2) |

485 |

6

565 |

|||||||||||

|

Ultimate Tensile Strength (N/mm2) |

485 |

6

565 |

|||||||||||

|

Ultimate Tensile Strength (N/mm2) |

485 |

6

565 |

|||||||||||

|

Ultimate Tensile Strength (N/mm2) |

485 |

6

565 |

|||||||||||

|

Ultimate Tensile Strength (N/mm2) |

485 |

6

565 |

|||||||||||

|

Ultimate Tensile Strength (N/mm2) |

485 |

6

565 |

|||||||||||

|

Ultimate Tensile Strength (N/mm2) |

485 |

6

565 |

|||||||||||

|

Ultimate Tensile Strength (N/mm2) |

485 |

6

565 |

|||||||||||

|

Ultimate Tensile Strength (N/mm2) |

485 |

6

565 |

|||||||||||

|

Ultimate Tensile Strength (N/mm2) |

485 |

6

565 |

|||||||||||

|

Ultimate Tensile Strength (N/mm2) |

485 |

6

565 |

|||||||||||

|

Ultimate Tensile Strength (N/mm2) |

485 |

6

565 |

|||||||||||

|

Ultimate Tensile Strength (N/mm2) |

485 |

6

565 |

|||||||||||

|

Elongation(%) |

14.5 |

12 |

16 |

20-25 |

18-24 |

18-24 |

|||||||

|

Total Elongation @ Max Force(%) |

- |

- |

5 |

- |

- |

8 to 10 |

|||||||

|

Ration (UTS/YS) |

1.16 |

1.09 |

1.13 |

1.15-1.25 |

1.13-1.22 |

1.14-1.25 |

|||||||