One of the most important materials needed for high quality construction is steel, which is consumed in form of bars and the best raw material to produce high quality steel bars is MS Billets. At Arihant Sales Network, we produce ideal billets that result in top quality steel bars.

Billet, being a semi-finished product, is used for feedstock to rolling mills for production of long products like wire rods, bars/rods and structural. Steel Billet is also used extensively in forge shops and machine shops for production of engineering goods and also as feedstock for seamless tubes.

Excellent Surface Finish: The Billets produced by ARIHANT are free from any surface crack or lamination. Magnetic particle test in order to identify any crack on the surface is done on a regular basis as per its Quality Management Plan. Dimensional Tolerance: Billets at ARIHANT are produced strictly in accordance to IS 2830 for dimensional tolerance.

No Internal Defects: The Billets produced are free from any internal defects. Defects such as piping blow-holes and pinholes are identified and segregated by Sulphur Print Test.

TMT Bars are thermo-mechanically-treated through leading world tempcore based technology for high yield strength. The process involves rapid quenching of the hot bars through a series of water jets after they roll out of the last mill stand. The bars are cooled, allowing the core and surface temperatures to equalize.

TMT bars or Thermo-Mechanically Treated bars are high-strength reinforcement bars having a tough outer core and a soft inner core. The very first step of the manufacturing process involves passing the steel wires through a rolling mill stand. Thereafter, these rolled steel wires are again passed through the Tempcore water cooling system. While passing the wires through the water cooling system, the water pressure is optimised. The sudden quenching and drastic change in temperature toughen the outer layer of the steel bar, thus making it super tough and durable. Once this process is over, the TMT bars are subject to atmospheric cooling. This is done in order to equalise the temperature difference between the soft inner core and the tough exterior. Once the TMT bar cools down, it slowly turns into a ferrite-pearlite mass. The inner core remains soft giving the TMT bar great tensile strength and elongation point.

Properties of Sponge Iron:-

Specifications:-

Manganese : 0.50% to 0.60%

Grade: Fe-415/500/550/600

Phos .: 0.05% max

Sulphur : 0.05% max

Carbon: 0.25% max

Size: 8 mm to 52 mm

|

SPECIFICATION OF TMT BARS WEIGHTS (Kg/Mtr) |

|||||||||||

| SIZE | IS-1786:2008 |

Arihant TMT |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Std |

Min |

Max |

Min |

Max |

|||||||

8mm |

0.395 |

0.367 |

0.423 |

0.370 |

0.385 |

||||||

10mm |

0.617 |

0.574 |

0.660 |

0.575 |

0.585 |

||||||

12mm |

0.888 |

0.844 |

0.932 |

0.845 |

0.860 |

||||||

16mm |

1.580 |

1.500 |

1.659 |

1.510 |

1.580 |

||||||

20mm |

2.470 |

2.395 |

2.544 |

2.400 |

2.450 |

||||||

25mm |

3.850 |

3.730 |

3.965 |

3.730 |

3.850 |

||||||

28mm |

4.830 |

4.685 |

4.975 |

4.700 |

4.830 |

||||||

32mm |

6.310 |

6.121 |

6.499 |

6.190 |

6.310 |

||||||

|

SPECIFICATION OF TMT BARS MECHANICAL PROPERTIES |

||||||||||||

|

Parameter |

IS-1786:2008 |

Sarthak TMT |

||||||||||

|

Fe-415 |

Fe-500 |

Fe-500D |

Fe-415 |

Fe-500 |

Fe-500D |

|||||||

|

Yield Stress(N/mm2) |

415 |

500 |

500 |

430-490 |

520-560 |

520-560 |

||||||

|

Ultimate Tensile Strength (N/mm2) |

485 |

545 |

565 |

500-560 |

600-680 |

600-680 |

||||||

|

Elongation(%) |

14.5 |

12 |

16 |

20-25 |

18-24 |

18-24 |

||||||

|

Total Elongation @ Max Force(%) |

- |

- |

5 |

- |

- |

8 to 10 |

||||||

|

Ration (UTS/YS) |

1.16 |

1.09 |

1.13 |

1.15-1.25 |

1.13-1.22 |

1.14-1.25 |

||||||

|

SPECIFICATION OF TMT BARS CHEMICAL COMPOSITION |

|||||||

|

Parameter |

IS-1786:2008 |

Sarthak TMT |

|||||

|

Fe-415 |

Fe-500 |

Fe-500D |

Fe-415 |

Fe-500 |

Fe-500D |

||

|

Carbon (C) |

0.30 |

0.30 |

0.25 |

0.18 - 0.25 |

0.18 - 0.23 |

0.16 - 0.22 |

|

|

Sulphur (S) |

0.06 |

0.055 |

0.04 |

0.035-0.055 |

0.025-0.050 |

0.020-0.035 |

|

|

Phosphorus (P) |

0.06 |

0.055 |

0.04 |

0.035-0.055 |

0.035-0.050 |

0.025-0.035 |

|

|

Sulphur + Phosphorus(S+P) |

0.11 |

0.105 |

0.075 |

0.070-0.110 |

0.060-0.100 |

0.045-0.070 |

|

High Carbon Silico Manganese alloys are developed under the supervision of highly qualified professionals with precise chemical specifications. Our expertise lies in manufacturing these high carbon alloys and carbon manganese alloys in standard as well as customized form to meet with the drawings and specifications of our esteemed clients.

Silicomanganese (SiMn), a ferroalloy with high contents of manganese and silicon, is made by heating a mixture of the oxides manganese oxide (MnO2), silicon dioxide (SiO2), and iron oxide (Fe2O3), with carbon in a furnace. They undergo a thermal decomposition reaction. It is used as a deoxidizer and an alloying element in steel.

Specifications:-

Mn .: 60% min

Silicon: 14% / 15% min

Phos .: 0.35% max

Sulphur : 0.04% max

Carbon: 2% max

Size: 10-125 mm

Ferromanganese, a ferroalloy with high content of manganese, is made by heating a mixture of the oxides MnO2 and Fe2O3, with carbon, usually as coal and coke, in either a blast furnace or an electric arc furnace-type system, called a submerged arc furnace. ... Ferromanganese is used as a deoxidizer for steel.

Ferro manganese is an alloy of iron and manganese containing usually about 80% manganese.

Ferro manganese is used mainly to counteract the bad effects of sulfur. It also acts as a deoxidizer and combines with sulfur, thereby improving the hot-working properties of the product. It imparts metallurgical properties such as increased strength, hardness toughness and hardenability.

Specifications:-

Mn .: 70% min

Silicon: 1.5% max

Phos.: 0.40% max

Sulphur : 0.05% max

Carbon: 8% max

Size: 10 mm to 125 mm

Iron ores are rocks from which metallic iron can be extracted. It is one of the most abundant rock elements, constituting about 5% of the Earth’s crust and is the 4th most common element in the world. It is abundant in Australia and mined mostly in Western Australia but is also common around the globe and is mined in around 50 countries. The quality of Australia’s iron ore is considered to be some of the best in the world.That is also used in India.

Iron ore is part of our every day lives and our modern world would look completely different without it. 98% of world iron ore is used to make steel, which accounts for over 90% of all metals used in the world. Steel is used in building for so many things, from cars, trains and ships through to the high rise buildings in our cities and the bridges that connect us. Steel is used to create pipes, cars, ships, engines, roofs, nails, nuts, bolts, tools, machinery, in building & construction, to make white goods, in manufacturing, food cans and much more.

Specifications:-

Fe.: 60% to 65%

SiO2 + Al2O3 : 0.5% max

LOI : 2% max

Phos.: 0.05% max

Sulphur : 0.05% max

T. I.: 88 +- 2%

Size: 5-20 mm

Iron ore fines are extracted from the Iron ore mines which are available naturally in the form of Rock Mountains in some parts of the world. The ores are rich in Iron oxides. Iron ore is the raw material which is further processed to form pig Iron, which is used in making steel as one of the main components. Iron ore fines are of around 0-10 mm in size. 98% of the mined Iron ore is used to make steel. It is been argued that Iron ore is more integral to the global economy than any other commodity, except perhaps oil. Ore with Fe% more than 60% can be fed directly into Iron-making Blast Furnace.

Specifications:-

Fe.: 58% to 63%

SiO2 + Al2O3 0.05% max

Phos .: 0.07% max

Sulphur : 0.07% max

Moisture: 5% max

Size: 0-6 mm

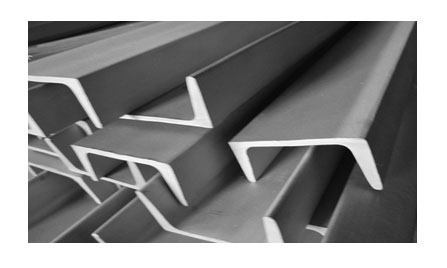

Structural steel is a category of steel construction material that is produced with a particular cross section or shape, and some specified values of strength and chemical composition. Structural steel composition, strength, size, shape, strength, and storage are controlled in most advanced countries. The word structural steel includes a broad variety of low carbon and manganese steels that are used in great numbers for civil and marine engineering applications. Numerous structural steels also include minor quantities of significant additions of other elements like Nb, V, Ti and Al. These are called High Strength Low Alloy or micro-alloyed steels. Structural steels are manufactured in section and plate shapes and are normally used in bridges, buildings, ships, and pipelines.

Properties:- Steel construction has so many advantages: the strength to weight ratio is excellent, metals join easily, efficient shapes are available, etc. With those advantages, though, come some challenges that are best solved by a good understanding of how the metals actually perform in a structure.

Specifications:- M. S. Channels, Angles & Beams available in all sizes & sections.

Steel is a dynamic, versatile and eco-friendly product with diverse use and applications. The liquid steel is solidified in cast iron moulds, which are placed on bottom pouring plate. The metal enters into the mould from bottom and rises up. In order to have ease in separating ingots from moulds, the moulds are tapered from top. Thus the ingots are also tapered from top. On the other hand, billets have same cross sectional area throughout its length. Billets are produced from Continuous casting Machine – CCM.

The following are the steps involved in the operation of a furnace

Specifications:- Available in all sizes & sections.

Pig iron is the product of smelting iron ore (also ilmenite) with a high-carbon fuel and reductant such as coke, usually with limestone as a flux. Charcoal and anthracite are also used as fuel and reductant.

Pig iron is produced by smelting or iron ore in blast furnaces or by smelting ilmenite in electric furnaces.

The vast majority of pig iron is produced and consumed within integrated steel mill complexes. In this context the term “pig iron” is something of a misnomer: within integrated steel mills, blast furnace iron is transferred directly to the steel plant in liquid form, better known as "hot metal" or "blast furnace iron." The term “pig iron” dates back to the time when hot metal was cast into ingots before being charged to the steel plant. The moulds were laid out in sand beds such that they could be fed from a common runner. The group of moulds resembled a litter of sucking pigs, the ingots being called “pigs” and the runner the “sow.”

Benefits in steelmaking and ferrous casting

Specifications:-

Available in Steel Grade and Foundry Grade

Silicon: below 1.5 %

Phos: 0.120 Max

Sulphur: 0.06 Max

Carbon: 3.8- 4.4 %

Mgn: 0.70

Size: 0-6 mm

We offer the finest quality MS Angles, which are extensively used in fabrication industry. The dimension is determined by the length and the unit measurement. We trust quality and productivity.

The dimension is determined by the length and the unit measurement. We trust quality and productivity.

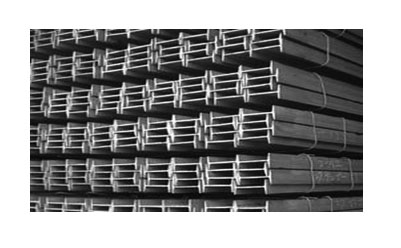

We offer the finest quality MS Beams & RS Joists which is the most sought after sections by the structural engineers, architects and construction.

The dimension is determined by the length and the unit measurement. We trust quality and productivity.

The sections are rolled strictly in accordance with IS 2062:2006 & is 808:1989

We offer the finest quality MS Channels, which are extensively used in fabrication industry. A channel is a right angle "C" section.

The dimension is determined by the length and the unit measurement. We trust quality and productivity.

Arihant sales network is engaged in offering a best quality range of Heavy Melting Scrap. These scraps are widely used in various industrial applications for making of more products. This scrap is available at affordable rates in the market.

Because of our vast experience, we have been successful in catering to the requirements of our esteemed clients by offering a qualitative range of Heavy Melting Scrap. As we never compromise with the quality of the products being offered by us, we are associated with the most reliable vendors of the market to obtain this range. Our products are made available by us in various specifications, in order th meet the variegated needs of our esteemed clients.

Features:-

Specifications:- Heavy Melting Scrap